When it comes to construction, we often hear about costs, timelines, and quality. But there’s one term that doesn’t come up as frequently, even though it plays a vital role in balancing all three: value engineering. It’s not as flashy as architectural design or as visible as construction progress, yet it quietly drives smart, cost-effective decisions behind the scenes.

So, what exactly is value engineering, and why should homeowners, developers, and project managers in Singapore pay attention to it? Whether you’re building a family home or embarking on a commercial build, understanding this concept can make all the difference between overspending and building smarter.

What is value engineering?

Value engineering is a systematic approach to improving the value of a project. It involves analysing the functions of a building, system, or component with the goal of achieving the necessary performance at the lowest total cost. That doesn’t mean cutting corners but about delivering the same or better results while minimising unnecessary expenses.

The process often starts during the design phase and continues throughout the construction cycle. A team of experts, typically including engineers, architects, and contractors, work together to identify opportunities to replace costly materials, simplify processes, or redesign elements in a more efficient way. The key is maintaining or even improving functionality, durability, and aesthetics while keeping costs manageable.

Why value engineering matters in construction

In a high-cost city like Singapore, every dollar counts in a construction project. Land prices, material costs, and labour expenses are all on the rise, especially for those embarking on large-scale or high-end residential builds. Without a clear value engineering strategy, it’s easy for budgets to spiral.

Value engineering helps keep projects realistic. It forces teams to justify every line item: why use a certain material? Is there a locally available alternative? Could modular components reduce labour hours? This mindset encourages collaboration and transparency, which are crucial for successful builds.

How it works: A practical breakdown

The value engineering process typically follows these steps:

1. Information gathering – Understand the full scope and functional requirements of the project.

2. Function analysis – Identify and define what each component must do (e.g. provide insulation, support weight, resist weathering).

3. Creative thinking – Brainstorm alternative methods or materials that could perform the same function.

4. Evaluation – Assess these alternatives based on cost, performance, sustainability, and feasibility.

5. Development – Develop the most promising ideas into fully fleshed-out solutions.

6. Presentation – Present recommendations to stakeholders for review and approval.

This process ensures that every decision is made with long-term value in mind.

Value engineering in residential projects

For those hiring a Singapore landed house builder, value engineering can help turn dream homes into practical realities without breaking the bank. For example, choosing imported materials instead of locally sourced ones could cut costs without sacrificing quality. Simplifying the design of a roofline or rethinking how utilities are laid out can also save time and money during construction.

Clients often have a wish list of features, like high ceilings, natural lighting, and smart home systems, but not all of them may be financially viable in their original form. Value engineering helps homeowners prioritise and adapt their vision so they can still achieve the look and feel they want while keeping the budget in check.

Value engineering isn’t a solo job. It works best when architects, engineers, and builders collaborate closely. This is why working with a general contractor who understands the local context, regulations, and market prices is critical. They can provide insights into which materials are available in Singapore, which methods speed up construction, and how to comply with URA, BCA and other authorities’ guidelines efficiently.

Furthermore, a seasoned contractor can foresee future maintenance issues. For example, specifying a high-end imported façade might look great now but become a maintenance nightmare later if parts or replacements aren’t locally available. Value engineering weighs such considerations so you’re not just saving today but also tomorrow.

Value engineering for commercial projects

The benefits of value engineering extend beyond residential builds. For businesses, retail outlets, and industrial developments, cost savings can multiply rapidly across larger square footage or multiple sites. A small change in flooring material across an entire facility could result in substantial savings, especially if it also reduces installation time and maintenance requirements.

Time is money in commercial construction. Delays mean lost revenue and increased overheads. Value engineering looks at ways to streamline timelines by pre-fabricating components offsite or choosing methods that require fewer labour hours. All of this adds up to a smoother, more predictable build.

Conclusion

Value engineering helps make the most of your construction budget without compromising on quality, safety, or style. It supports better decision-making, enhances collaboration, and ensures every component of your build delivers true value.

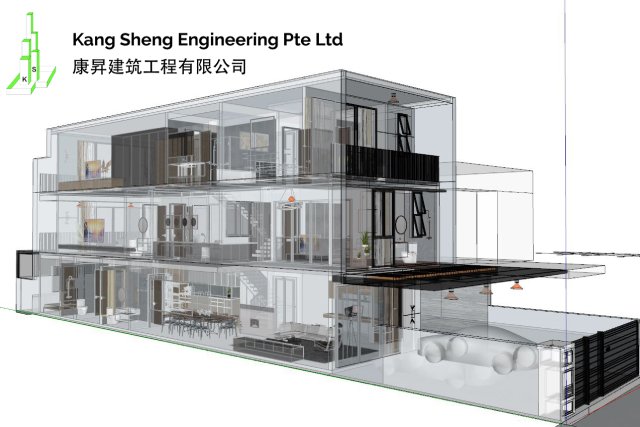

At Kang Sheng Engineering, we bring value engineering into every project we handle, whether you’re building a home or developing a commercial space. As a trusted provider of design-build services and general contracting services, we’re here to help you build smart, build strong, and build with confidence. Reach out to our team today and discover how we can support your construction journey.