There are few industries that juggle as many risks as construction. A risk, in this context, is any event that could derail your plans, and in building projects, the list of possibilities is long. From compliance issues and subcontractor disputes to site-specific hazards, every project comes with its own set of challenges.

And when it comes to commercial construction in Singapore, those challenges multiply. Singapore’s strict regulations and limited space mean that contractors, engineers, and project owners face unique hurdles at every stage. Construction sites often sit close to schools, roads, or operational facilities, so even the smallest misstep can have a significant impact. These setbacks not only delay timelines and inflate costs but can also raise safety concerns.

The best way to minimise risk in construction is to be proactive. By learning from common mistakes in the industry, you can plan ahead, adapt when challenges arise, and ensure your project crosses the finish line within budget. That’s why working with experienced professionals matters, because the right contractors can save you money and time on builds while helping you avoid critical errors.

Key risk areas in construction projects

Risk management in construction has been extensively studied, with academics and professionals classifying risks into several categories. These include:

- Design risks: Errors, omissions, or late-stage changes to the design can cause major disruptions. If contractors don’t execute work in line with the contract, costly rework may be required.

- External risks: These range from new stakeholders making demands to sudden changes in laws, taxes, or local standards. Public objections or neighbouring developments can also trigger delays.

- Environmental risks: The project’s surroundings can pose risks, such as flooding, soil instability, or protected green spaces.

- Project management risks: Poor scheduling, resource allocation, or supervision can unravel even the most promising build.

- Organisational risks: These stem from the contractor’s own team – think delayed deliveries, high staff turnover, or inexperienced workers.

- Right of way risks: Issues related to permits, access, or conflicting land use rights can stall projects indefinitely.

- Construction risks: Cost overruns, poor workmanship, or the misuse of new technologies often land in this category.

Of these, design delays and errors frequently top the list. That’s why it’s essential to classify mistakes correctly; understanding the source of the risk is the first step towards preventing it.

What is the margin of error in construction?

Mistakes in construction aren’t always catastrophic. In fact, most projects include a recognised “margin of error.” This allowance accounts for uncertainties in cost estimates and timelines. For instance, materials may cost more than projected due to inflation, or unexpected weather could push back schedules. By factoring in these variances, builders create a buffer that helps projects remain resilient when unforeseen issues arise.

Common factors that influence the margin of error include:

- Inflation: Rising labour and material costs can widen the gap between estimates and reality.

- Supply chain issues: Delays and shortages often create ripple effects throughout the project.

- Project complexity: The more variables involved, the larger the potential for deviation.

- Regulatory changes: Modifications in permits or inspection standards can unexpectedly alter costs or timelines.

Acknowledging the margin of error doesn’t excuse poor planning; it simply makes projects more adaptable when circumstances change.

Critical mistakes to avoid in commercial construction

Learning from past missteps is one of the best ways to save time and money in the construction industry. Here are the most common mistakes in commercial projects and how to steer clear of them.

1. Failing to meet full compliance with Singapore’s building regulations

Singapore enforces some of the strictest building codes in the region, covering everything from fire safety to accessibility. Skipping over these requirements or assuming they’ll “work themselves out” can spell disaster. Non-compliance may result in heavy fines or even a complete project shutdown.

Paperwork delays are also common, with approvals sometimes stalling procurement, budgeting, or site access. If your plans are rejected, redesigns can be expensive and time-consuming. To prevent these setbacks:

- Engage consultants early who are familiar with local regulations.

- Break large submissions into smaller packages to gain partial approvals faster.

- Track every submission and follow up diligently.

2. Choosing the wrong subcontractors

The subcontractors you hire will have a direct impact on the quality of your project. Going with the cheapest option may seem attractive, but it often leads to poor workmanship and costly rework.

Instead, thoroughly vet each subcontractor. Check their track record, verify certifications, and request references. The right contractor will ensure your project stays on time, on budget, and up to standard. This lesson is just as true in residential projects, where engaging a reliable landed house builder can make the difference between a smooth process and endless delays.

3. Providing insufficient leeway in the project timeline

One of the most common mistakes is creating an unrealistic schedule. While everyone wants to finish as quickly as possible, failing to account for unexpected delays sets the project up for disappointment. Factors like weather, late deliveries, or labour shortages are inevitable. Build contingency time into your timeline so that small hiccups don’t derail the entire project.

4. Ineffective communication

In projects with multiple stakeholders (contractors, engineers, designers, clients, and regulators), clear communication is everything. Misunderstandings can lead to missed deadlines, conflicting expectations, and unnecessary tension.

Establish communication protocols early. Use regular meetings, digital tracking tools, and transparent reporting to keep everyone aligned. Doing so prevents minor issues from snowballing into major disputes.

5. Improper foundation work

Cutting corners in the foundation stage is one of the costliest mistakes a builder can make. Poor soil preparation, weak concrete, or overlooking environmental conditions like soil moisture often lead to cracking, settling, or even structural collapse later. Always invest in proper site surveys and soil testing before laying the foundation.

6. Neglecting safety procedures

Safety isn’t just about avoiding fines but also about protecting workers and maintaining a disciplined site. Accidents still happen when protocols are ignored, often resulting in injuries, lawsuits, and project delays. Make safety a core part of your culture by conducting regular training, enforcing protective gear use, and carrying out routine inspections.

7. Insufficient site setup

Before construction begins, site preparation must be thorough. Clearing debris, grading land, ensuring drainage, and stabilising the ground are all vital. Skipping these steps may cause uneven surfaces, soil erosion, or water damage, which are issues that are far more expensive to fix once building is underway.

8. Not managing change orders properly

Change is inevitable in construction, whether due to design updates, material shortages, or evolving business needs. The danger lies in handling change orders informally. If undocumented or poorly communicated, they can cause budget overruns and scheduling chaos.

Establish a documented process from day one. Each change should clearly outline scope, cost, timeline impact, and require formal approval. Using digital platforms for tracking ensures accountability and transparency.

9. Failing to expect the unexpected

Even with the best planning, surprises will arise. Weather, budget adjustments, or staff turnover can upend the smoothest schedules. Good contractors plan for contingencies, having not just a plan B, but a plan C, D, and E as well. Flexibility and foresight are key qualities that separate successful projects from struggling ones.

Conclusion

Commercial construction projects in Singapore are no small feat. The combination of various factors makes it one of the most challenging industries around. Yet, with proper planning, attention to detail, and a willingness to learn from common mistakes, these challenges can be overcome. By ensuring compliance, choosing the right partners, building realistic timelines, and preparing for the unexpected, you’ll not only avoid costly errors but also lay the groundwork for a project that is safe, efficient, and built to last.

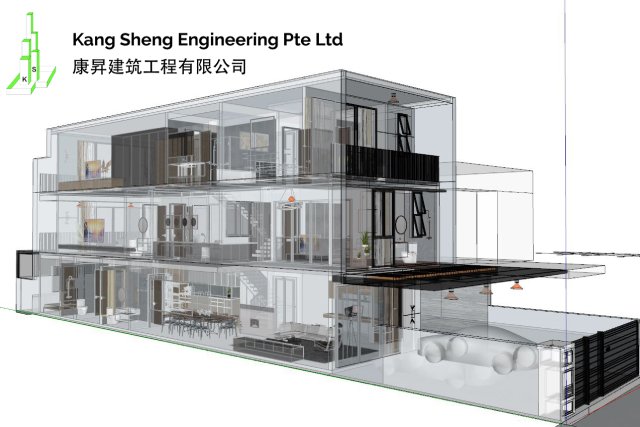

Avoiding costly missteps starts with having the right partner by your side. At Kang Sheng Engineering, we provide end-to-end design-build and general contracting services that align with Singapore’s strict compliance standards. Let our expertise help you sidestep common pitfalls and ensure your commercial project is completed smoothly, on time, and with lasting quality.